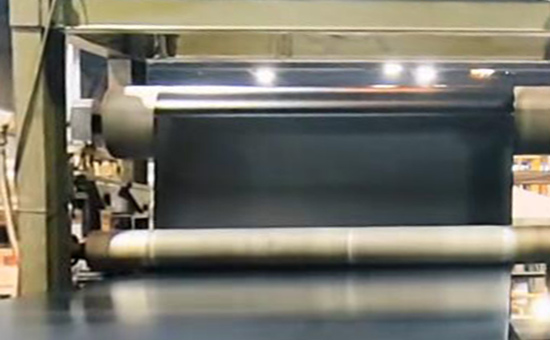

Calendering is the process of extrusion of the rubber material through the relative rotation of the roller gap of the special calendering equipment to expand into a film with a certain specification and shape, or to make the surface of textile materials and metal materials realize the process of hanging glue, which has high technical requirements. When using recycled rubber to produce thin, thin-walled, long strips or strips, the calendering process is often used. Recycled rubber product manufacturers can meet higher precision calendering requirements through reasonable formulation design.

1. Four requirements that need to be met by calendered compounds

(1) Suitable roller wrapping: The recycled rubber material on the roller of the calender can neither be removed nor glued to the roller, which should be convenient for calendering operation and easy to produce sheets.

(2) Good fluidity: make the rubber penetrate smoothly and evenly into the fabric or cord thread; Compared with natural rubber and synthetic rubber, the rubber mixed with recycled rubber has better fluidity and is easy to calender.

(3) Sufficient scorching resistance: the recycled rubber needs to be hot-tempered (rough and fine) before calendering, and is subjected to a roller temperature of 60-80 °C and multiple thinning passes; The calendering process is generally carried out at a high temperature of 80-110°C, so the calendering compound cannot be scorched during the calendering process; Normally, the scorching time of calendered compound at 120°C should be 20-35min.

(4) It has a low shrinkage rate: reduce the elastic deformation of the rubber material, so that the surface of the recycled rubber calendered film or tape is smooth and the size specification is accurate.

2. How to adjust the formula to improve the calendering performance of recycled rubber

(1) Design of recycled rubber filling system

The use of reinforcing fillers in recycled rubber can effectively improve the strength of the compound and improve the rolling properties of the compound. After adding fillers, the recycled rubber calendered rubber will reduce the glue content of the rubber material, reduce the elastic deformation of the rubber material, and reduce the shrinkage rate. Different fillers have different degrees of influence, and generally fillers with high structure and small particle size have a small calendering shrinkage rate. Recycled rubber calenders should avoid or reduce the use of anisotropic magnesium carbonate, talc and other fillers to eliminate the calendering effect.

Different types of calendering have different requirements for the variety and amount of fillers. For example, when pressing, it is required to use a large amount of filler to ensure that the pattern is clear, and the glue content is as high as 40% or more when rubbing the glue.

(2) Design of recycled rubber softening system

The addition of softener to the compound can reduce the intermolecular force, shorten the relaxation time, increase the fluidity of the compound, and reduce the shrinkage rate. The selection of softeners in recycled rubber calendered compounds needs to be determined according to the specific requirements of the calendered compounds E5LYY327 when calendered compounds are required to have a certain stiffness, softeners with high viscosity such as oil paste and coumalone resin should be selected; Adhesive or rubbering requires good fluidity and can penetrate among the cords, and softeners with large plasticizing effect and low viscosity should be selected, such as petroleum-based oil, pine tar, etc.

The calendering process can carry out the calendering, pressing, lamination of film, and the calendering of textile hanging glue and steel wire cord; To improve the calendering process of compounds, manufacturers of recycled rubber products can also appropriately adjust the production process parameters, such as roll temperature, roll speed, calendering tension and roll spacing, etc., and continue to discuss related issues with you later.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits