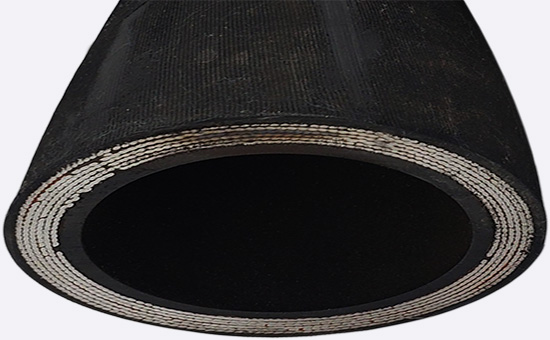

The buried suction hose is composed of an outer layer of rubber, a middle layer of rubber and an inner layer of rubber, which is mainly used in industrial and mining, water conservancy, farmland irrigation and other fields. Compared with reclaimed rubber, the processing technology of reclaimed rubber powder is simpler and more environmentally friendly, can it be used in the production of buried suction hoses? What role can it play?

1. The role of reclaimed rubber powder in the thread suction hose

Rubber powder is an important means of waste rubber recycling, and a certain amount of reclaimed rubber powder can effectively reduce the cost of raw rubber by mixing a certain amount of reclaimed rubber powder in the middle and inner layers of the buried suction hose. Reclaimed rubber powder contains rubber E4LYY326 components and compounding agents, which can improve the synthesis of rubber compounds, especially the strength after aging, and delay the service life of suction hoses. The reasonable mixing of rubber powder in the buried suction hose can not only ensure the mechanical strength and aging resistance of each adhesive layer of the hose, but also improve the adhesion of the rubber material, and facilitate the formation of the hose.

2. Thread suction hose middle layer rubber vulcanization formula

(1) Mixed rubber powder: 100 parts of natural rubber, 250 parts of recycled rubber, 5 parts of zinc oxide, 2.5 parts of stearic acid, 1.5 parts of antioxidant, 40 parts of carbon black, 200 parts of recycled powder, 29 parts of softener, 1.7 parts of accelerator, 3.6 parts of vulcanizing agent; Total 633.3 copies.

(2) Unglued powder: 40 parts of natural rubber, 60 parts of oil-filled styrene-butadiene rubber, 220 parts of recycled rubber, 5 parts of zinc oxide, 2.5 parts of stearic acid, 1.5 parts of antioxidant, 55 parts of carbon black, 100 parts of light calcium, 11 parts of softener, 1.9 parts of accelerator, 2.9 parts of vulcanizing agent; Total 499.8 copies.

3. Adhesive vulcanization formula for the inner layer of the thread suction hose

(1) Mixed rubber powder: 100 parts of natural rubber, 220 parts of recycled rubber, 5 parts of zinc oxide, 2.5 parts of stearic acid, 1.5 parts of antioxidant, 40 parts of carbon black, 85 parts of light calcium, 90 parts of vulcanized rubber powder, 18 parts of softener, 1.7 parts of accelerator, 3.6 parts of vulcanizing agent; Total 567.3 copies.

(2) Unadded rubber powder: 100 parts of natural rubber, 220 parts of recycled rubber, 5 parts of zinc oxide, 2.5 parts of stearic acid, 1.5 parts of antioxidant, 40 parts of carbon black, 80 parts of light calcium, 80 parts of clay, 16 parts of softener, 1.7 parts of accelerator, 3.6 parts of vulcanizing agent, a total of 550.3 parts.

As a product of waste rubber recycling, reclaimed rubber powder has a low price, which can reduce costs and improve the performance of rubber materials in the production of rubber hoses. When the middle layer of glue and the inner layer of the buried suction hose are mixed with reclaimed rubber powder to reduce costs, it is necessary to select the appropriate rubber powder variety according to the application environment and requirements of the hose, reasonably control the mixing ratio of rubber powder, ensure the uniform distribution of rubber powder in the rubber material, and ensure the quality and yield of the finished product of the buried suction hose.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits