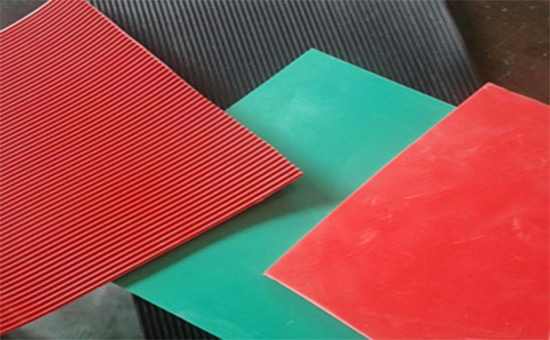

Rubber mats are sheet or plate rubber products with a certain shape, thickness, elasticity and function processed from natural rubber or synthetic rubber as raw materials. Natural latex recycled rubber has the basic performance characteristics of natural rubber, high strength, good elasticity, small specific gravity, can replace natural rubber in whole or in part, general synthetic rubber to produce rubber mats, pay attention to the following points, can effectively reduce the cost of raw materials under the premise of ensuring the performance of rubber pads.

1. Choose skills for latex recycled rubber for rubber pads

When using latex recycled rubber alone or in combination with natural rubber or synthetic rubber to produce rubber pads, try to choose latex recycled rubber with high Mooney viscosity without affecting the processing performance to ensure the E5LYY821 elongation of the rubber mat. Choose latex recycled rubber with 60 mesh or more, better mixing and dispersion, and the surface of the rubber pad is not easy to appear pockmarks, pores, graininess, etc.; For rubber mats with environmental protection requirements, it is recommended to choose recycled rubber that has passed EU ROHS certification; Choose latex recycled rubber produced by regular recycled rubber factories, which is of good quality, not easy to run out of stock, and can be supplied stably for a long time.

2. Control the proportion of latex recycled rubber in rubber pads

When using latex recycled rubber to reduce the production cost of rubber mats in different use situations, the proportion of latex recycled rubber is different, and 30%-50% of latex recycled rubber can be mixed with rubber mats with high performance requirements. The rubber mat with general performance requirements can be mixed with 50%-70% natural recycled rubber; Low-cost rubber mats can be used entirely on latex recycled glue, and if necessary, latex recycled rubber can be used in conjunction with lower-priced tire recycled rubber to reduce costs.

3. Adjust the formula of latex recycled rubber mixed with rubber pads

When using latex recycled rubber in rubber mat formulation to reduce costs, it is necessary to adjust the rubber product formulation appropriately.

(1) Vulcanization system

Latex recycled rubber contains the original vulcanization network fragments of waste rubber products, and a part of the accelerator and sulfur will be consumed during the processing process, so it is necessary to appropriately increase the amount of sulfur and accelerator in the rubber pad formula, on the basis of the original formula, the amount of sulfur can be increased by 5%-15%, and the total amount of accelerator can be increased by 10%-30%; If necessary, an effective vulcanization system or a semi-effective vulcanization system can be used, and the vulcanized rubber has better heat resistance and aging performance.

(2) Reinforcement filling system: Appropriately increase the reinforcement agents in the formula of rubber mats containing latex recycled rubber (commonly used carbon black N300 and N550) to improve the physical and mechanical strength of the finished rubber mats.

(3) Softening and plasticization system: Latex recycled rubber adds softener in the production process, so in the rubber pad formula containing natural recycled rubber, the amount of softener needs to be appropriately reduced, and oil can even be added in the early stage; Too much softener can easily lead to sticky hands, plummeting strength, and excessive permanent deformation of the rubber mat.

4. Rubber pad mixed with latex recycled rubber process adjustment

(1) Compounding: Latex recycled rubber can be thin-passed plasticized separately, or premixed with some raw rubber and small materials, with better uniformity, and the mixing temperature should not be too high to prevent the rubber from burning.

(2) Vulcanization: When the rubber mat is mixed with latex recycled glue, the vulcanization meter data needs to be re-measured, and it is recommended to extend the vulcanization time appropriately to ensure that the thick product or the central part is fully vulcanized; The vulcanization temperature is basically unchanged.

Rational use of latex recycled rubber can produce high-performance, low-cost rubber mats, and later share with you the production formula of different varieties of rubber mats of latex recycled rubber.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits