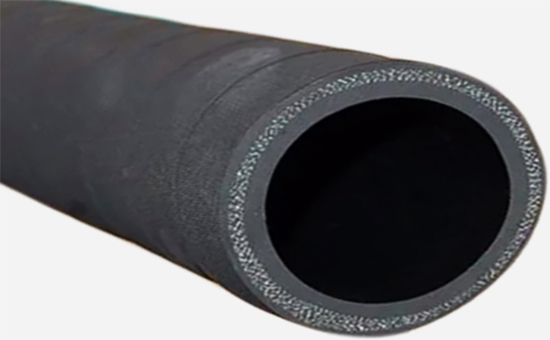

Acid-resistant cloth hoses are mainly used to convey corrosive media, including inner rubber layer, wiping rubber layer, outer rubber layer, etc., and some hoses contain a reinforcing layer, which is generally processed with natural rubber, styrene-butadiene rubber, and butadiene rubber as the main raw materials. As a renewable resource for waste rubber recycling, reclaimed rubber has the characteristics of low price, easy processing and aging resistance, and can be mixed into different rubber layers of acid-resistant cloth hoses in an appropriate proportion to effectively reduce the cost of raw materials.

1. Acid-resistant cloth cloth cloth hose inner layer rubber vulcanization formula

30 parts of natural rubber, 70 parts of styrene-butadiene rubber, 40 parts of recycled rubber, 5 parts of zinc oxide, 2 parts of stearic acid, 2 parts of antioxidant A, 1.5 parts of antioxidant D, 1 part of paraffin, 40 parts of carbon black N330, 30 parts of clay, 25 parts of barium sulfate, 15 parts of graphite powder, 5 parts of asphalt, 18 parts of coumaron resin, 2.8 parts of accelerator DM, 2.2 parts of accelerator TMTD; Total: 289.5 copies.

2. Acid-resistant cloth hose, cotton canvas rubber, rubber, mixed with reclaimed rubber vulcanization formula

70 parts of natural rubber, 30 parts of styrene-butadiene rubber, 70 parts of recycled rubber, 4 parts of zinc oxide, 0.5 parts of stearic acid, 1 part of antioxidant A, 15 parts of carbon black N330, 20 parts of light calcium, 30 parts of clay, 9 parts of pine tar, 4 parts of coumaron resin, 3.5 parts of rosin, 9 parts of heavy oil, 2.3 parts of accelerator DM, 0.8 parts of accelerator M, 0.2 parts of accelerator TMTD, 3.3 parts of sulfur; Total: 272.6 copies.

3. Acid-resistant cloth jacket hose, canvas rubber, rubber, mixed with reclaimed rubber vulcanization formula

70 parts of natural rubber, 30 parts of styrene-butadiene rubber, 35 parts of recycled rubber, 4 parts of zinc oxide, 0.5 parts of stearic acid, 2 parts of antioxidant A, 15 parts of carbon black N330, 15 parts of light calcium, 20 parts of clay, 10 parts of heavy oil, 10 parts of pine tar, 7 parts of coumaron resin, 2.5 parts of adhesive A, 3.5 parts of adhesive RS, 1.2 parts of accelerator DM, 0.1 part of accelerator TMTD, 0.8 parts of accelerator NOBS, 3.4 parts of sulfur; Total: 230 copies.

The rubber layer in the acid-resistant cloth hose requires the rubber material used to have good compactness, adaptability to the conveying medium, as well as certain elasticity, softness and aging resistance; Wiping adhesive requires that the rubber material has good fluidity, has a certain permeability to the fabric, can penetrate deep into the fiber and the structure of the fabric, so as to improve the adhesive strength of each component, and has a certain strong elongation performance and bending and fatigue resistance.

In actual production, the outer layer of acid-resistant cloth hose can also be mixed with reclaimed rubber in an appropriate amount, which is required to meet the needs of the use environment and working conditions, and has good wear resistance and tear resistance. When designing the formula of each adhesive layer of the acid-resistant rubber board containing reclaimed rubber, it is also necessary to consider the processing performance of each adhesive layer, including the E4LYY125 matching among the vulcanization speed of each adhesive layer. The semi-finished product has sufficient stiffness, small shrinkage, smooth surface of extrusion and calendering, and is easy to form. In the future, we will continue to discuss with you the key points of the processing technology of each adhesive layer of reclaimed rubber preparation of acid-resistant cloth jacket hose.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits