The main chain of EPDM rubber is composed of chemically stable saturated hydrocarbons and has excellent heat resistance; EPDM reclaimed rubber retains the excellent heat resistance and ozone resistance of the original EPDM rubber, and both are widely used Produce all kinds of heat-resistant rubber products. When using EPDM rubber to produce rubber seals and other products, the vulcanization system directly affects the heat aging resistance of the rubber during compression and deformation, and then affects the performance and life of the finished product.

1. Sulfur vulcanization system

When using sulfur vulcanization system to prepare low compression set of EPDM vulcaniz Used in conjunction with Dimorpholine. Studies have shown that 0.5 parts of sulfur, 3 parts of zinc dibutyl dithiocarbamate, 3 parts of zinc dimethyl dithiocarbamate, 2 parts of dithiodimorpholine, and 3 parts of accelerator TMTD can be used together to prepare compression The compound with the lowest permanent deformation.

In actual production, with 1 part of sulfur, 2 parts of accelerator NS, 1 part of accelerator TMTD, and 2 parts of zinc dialkyl dithiophosphate, the EPDM vulcanizate has better thermal stability and lower compression set , Vulcanizate has better heat resistance during compression deformation.

2. Peroxide curing system

Peroxide is one of the most commonly used vulcanizing agents in addition to sulfur in the production of rubber products. The peroxide vulcanized rubber will generate C-C crosslinking agent, which has high bond energy, good chemical stability, and excellent thermal and oxygen aging resistance of the vulcanized rubber.

In actual production, when EPDM rubber or EPDM reclaimed rubber is vulcanized with peroxide, the vulcanized rubber has better heat resistance and lower compression set. Theoretically, the heat resistance of EPDM vulcanizate during compression deformation is better than that of two Ethylene propylene rubber 2YLYY108 peroxide vulcanizate is good. In the EPDM peroxide vulcanization system, the appropriate amount of TAC, TAIC, TATM and other active agents containing multiple or double bonds can improve the compression set and heat resistance of the EPDM vulcanizate.

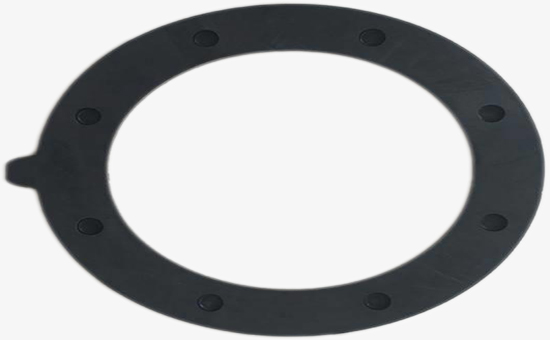

The stress relaxation of EPDM peroxide vulcanizates in inert media and air is caused by the breakage of rubber molecular chains, while sulfur vulcanizates are caused by the destruction of polysulfide bonds. EPDM rubber vulcanizates, especially peroxide vulcanizates, have a sharp increase in stress relaxation speed in the presence of oxygen in the air. When using EPDM rubber, EPDM reclaimed rubber, or EPDM/reclaimed rubber combined to produce rubber seals, manufacturers must choose a suitable vulcanization system to improve the resistance of EPDM rubber during compression deformation. Thermal, further optimize the comprehensive index of the finished product and extend the service life.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits