Heat-resistant rubber products maintain good physical and mechanical properties and use performance after enduring long-term thermal aging. The main chain of ethylene propylene diene monomer (EPDM) rubber is composed of chemically stable saturated hydrocarbons, only containing unsaturated double bonds in the side chain. It has excellent aging resistance, such as ozone resistance, heat resistance, and weather resistance, and can be used to produce various types of heat-resistant rubber products. EPDM recycled rubber retains the basic performance characteristics of EPDM rubber, and can be used alone or in combination with EPDM raw rubber, butyl rubber, etc. to produce heat resistant rubber products, effectively reducing production costs.

Application skills of ethylene propylene diene monomer recycled adhesive in heat resistant plywood

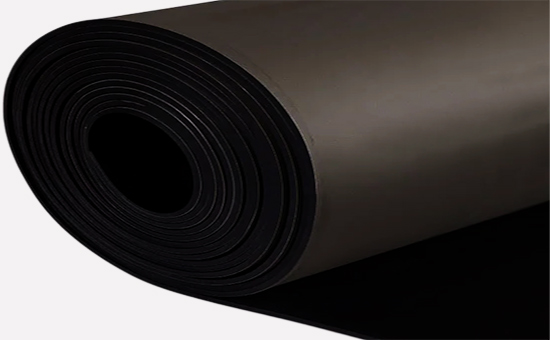

Heat-resistant rubber sheets require that the rubber material have excellent heat resistance. EPDM recycled rubber can be used alone or in combination with EPDM, butyl rubber, and butyl recycled rubber to produce heat resistant rubber sheets. When using EPDM recycled rubber to produce heat resistant rubber sheets, peroxide vulcanization is generally used; Appropriate use of fillers with good heat resistance such as white carbon black, zinc oxide, magnesium oxide, and silicate; Avoid using softeners that are easy to migrate and volatilize at high temperatures. It is recommended to use polyester plasticizers or reactive softeners; Using high efficiency heat resistant antioxidant and increasing the dosage appropriately can combine two or more antioxidants to further improve the heat resistance of EPDM recycled heat resistant rubber sheets.

Application skills of ethylene propylene diene monomer recycled adhesive in heat resistant conveyor belts

Heat-resistant rubber conveyor belt covering rubber requires good heat resistance of the rubber material. EPDM recycled rubber can be used alone or in combination with EPDM to produce heat resistant conveyor belt covering rubber, such as canvas core heat resistant conveyor belt covering rubber. When using EPDM recycled rubber in heat resistant conveyor belts, peroxide or low sulfur vulcanization systems are often used; Use high wear resistant carbon black and gas mixed carbon black for reinforcement, appropriately increase the hardness of the rubber compound, and prevent high-temperature cracking; Softeners can be selected from paraffin oil, coal tar, chlorinated paraffin, solid coumarone, and other softening plasticizers that have low volatility at high temperatures and low thermal decomposition temperatures; Use antioxidant MB, 2246, etc. to improve the heat resistance of EPDM recycled rubber heat resistant conveyor belts.

Application skills of ethylene propylene diene monomer recycled adhesive in heat resistant rubber tubes

For heat resistant rubber pipes with high temperature requirements, EPDM rubber, butyl rubber, silicon and fluorine rubber are often used for processing. EPDM recycled rubber can be used together with appropriate amounts of EPDM and butyl rubber to produce heat resistant rubber pipes. When using EPDM/recycled rubber 2SLYY329 to produce heat resistant rubber tubes, peroxide vulcanization can be used; Using semi reinforced carbon black or universal furnace black for reinforcement, light colored inorganic fillers can be filled in an appropriate amount; Select a petroleum based operating oil with a boiling point.

In actual production, EPDM recycled rubber can also be used alone or in combination with EPDM and butyl rubber to produce heat resistant rubber sealing products such as heat resistant O-rings, heat resistant sealing strips, and other heat resistant rubber products. The following editor will continue to discuss with you the application techniques of EPDM recycled rubber in heat resistant rubber products.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits