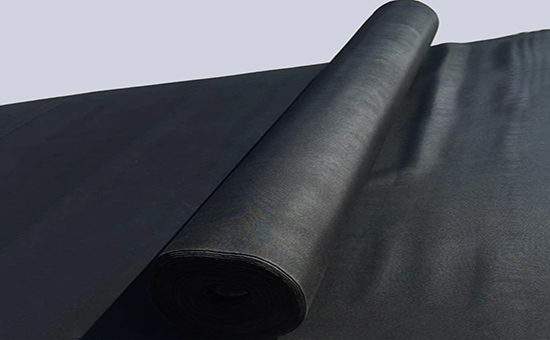

EPDM has excellent high temperature resistance, weather resistance, and ozone resistance, making it an ideal raw material for the production of rubber waterproof membranes. However, the price of EPDM recycled rubber is very high, and the cost pressure of fully using EPDM to produce waterproof membranes is greater in the increasingly fierce market competition; As an option raw material for high-priced raw rubber, can recycled rubber be used in EPDM waterproof membrane? How does EPDM rubber waterproofing membrane use recycled rubber to further reduce costs? What issues should I pay attention to?

1. What recycled glue can be used in EPDM waterproof membrane?

(1) EPDM recycled rubber: It is processed from EPDM head adhesive, unvulcanized EPDM rubber or waste EPDM rubber products (such as automobile sealing strips) as raw materials, which retains the basic performance characteristics of EPDM and has good compatibility with EPDM rubber, and can replace EPDM raw rubber in whole or in part to produce waterproof membranes and reduce raw material costs.

(2) Butyl recycled rubber: processed from waste butyl inner tubes as raw materials, with good air tightness, heat resistance, corrosion resistance, the appropriate use of butyl recycled rubber in EPDM waterproof membrane can not only reduce the cost of raw materials, but also improve the processing process performance of rubber and the aging resistance of finished products.

2. Selection skills for recycled rubber in EPDM waterproof membrane

When using EPDM recycled rubber or butyl recycled rubber to replace some EPDM primary rubber to produce rubber waterproof membranes, it is recommended to give priority to recycled plastics with high ethylene propylene content (or butyl content) and low impurities.

3. How much recycled glue is suitable for EPDM waterproofing membrane?

When using recycled rubber to reduce the cost of EPDM rubber waterproofing membrane, the mixing ratio of recycled rubber can be adjusted according to performance needs and cost budget. Generally E5LYY87 low-grade waterproof membrane can be completely used with EPDM recycled glue, and can also be used in conjunction with butyl recycled rubber if necessary; In the middle and high-end waterproof membranes, 25%-50% EPDM recycled adhesive can be mixed, taking into account the cost and performance, which can not only reduce the cost by 30%-50%, but also maintain the basic weather resistance and tear resistance of the original rubber.

4. The formula and process of EPDM waterproof membrane mixed with EPDM recycled glue

When using recycled rubber in the formulation of EPDM waterproof membrane to reduce costs, it is necessary to appropriately increase the amount of sulfur by 10%-15%, and add calcium oxide to prevent foaming when hot air is vulcanized; Appropriately increase the amount of reinforcing agents such as carbon black, and reduce the operating oil to prevent shrinkage. When mixing rubber, it is recommended to appropriately extend the mixing time to ensure that the recycled rubber and EPDM primary rubber are evenly mixed to avoid local performance differences.

The rational use of recycled rubber in EPDM waterproof membrane can reduce the cost of raw materials, and can improve the performance of rubber processing technology and finished product use.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits