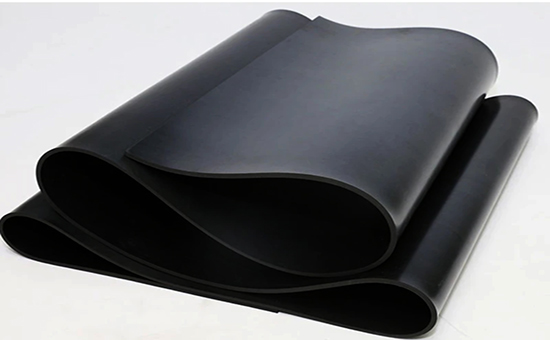

Nitrile reclaimed rubber has excellent oil resistance, abrasion resistance and aging resistance, which can replace nitrile primary rubber rubber to produce various types of rubber sheets and reduce costs. In actual production, nitrile reclaimed rubber can be used alone or in combination with nitrile rubber, neoprene, etc. to produce oil-resistant rubber sheets, conductive rubber sheets and sponge rubber sheets; Reasonable design of rubber sheet containing nitrile reclaimed rubber can further optimize the performance of rubber sheet while reducing costs, and meet the needs of more use occasions.

1. Application of nitrile reclaimed rubber in oil-resistant rubber sheet

(1) Oil-resistant rubber board mixed with nitrile reclaimed rubber formula design

When nitrile reclaimed rubber and nitrile rubber are used together to produce oil-resistant rubber sheets, sulfur vulcanization is generally used, and the dosage is controlled among 1.5-3 parts. In the filling system, the combination of carbon black, clay, calcium carbonate or calcium silicate and the appropriate increase in the amount of filler E4LYY612 can further improve the oil resistance of nitrile recycled rubber plate. It should be noted that when nitrile rubber/reclaimed rubber is used together to produce oil-resistant rubber sheets, it is recommended to use low-molecular polyethylene or ointment that is not extracted by oil as a softener, and aromatic oil or ester is generally used.

(2) Oil-resistant rubber sheet is mixed with nitrile reclaimed rubber vulcanization formula

70 parts of nitrile rubber, 30 parts of nitrile reclaimed rubber, 4 parts of zinc oxide, 1.8 parts of stearic acid, 2 parts of antioxidant RD, 1.5 parts of paraffin, 30 parts of carbon black N330, 30 parts of carbon black N774, 35 parts of clay, 90 parts of stone powder, 20 parts of dibutyl phthalate, 1 part of accelerator CZ, 0.5 parts of accelerator D, 1.5 parts of accelerator DM, 2 parts of sulfur; Total 319.3 copies.

2. Application of nitrile reclaimed rubber in conductive rubber sheet

(1) Conductive rubber plate mixed with nitrile reclaimed rubber formula design

Conductive rubber sheets require small insulation resistance, and more polar rubbers such as nitrile butadiene rubber and neoprene are selected; Appropriate amount of nitrile reclaimed rubber can effectively reduce costs. When nitrile rubber/nitrile reclaimed rubber is used together to produce conductive rubber sheets, it is necessary to balance the conductivity with other properties of the rubber sheets, and acetylene carbon black and conductive carbon black with high structure are generally used to fill; Appropriate amount of metal powder can improve the conductivity of the rubber compound; Phosphate ester plasticizers are recommended.

(2) The conductive rubber plate is mixed with nitrile reclaimed rubber vulcanization formula

80 parts of nitrile rubber, 20 parts of nitrile reclaimed rubber, 5 parts of zinc oxide, 1.5 parts of stearic acid, 1.5 parts of antioxidant D, 20 parts of super-reinforcing agent SR, 28 parts of clay, 33 parts of light calcium carbonate, 55 parts of acetylene carbon black, 22 parts of dibutyl phthalate, 0.7 parts of accelerator CZ, 1.5 parts of accelerator DM, 1.8 parts of sulfur; Total 270 copies.

3. Application of nitrile reclaimed rubber in sponge rubber board

(1) The sponge rubber board is mixed with nitrile reclaimed rubber formula design

Nitrile reclaimed rubber has excellent oil resistance and good hand elasticity, and can be used alone or combined with nitrile rubber to produce oil-resistant sponge rubber sheets, effectively reducing the cost of raw materials. The commonly used foaming agents include foaming agents H, OBSH, etc.;Foaming agent H is suitable for nitrile reclaimed rubber system, and the dosage is controlled among 3-5 parts, which can form a uniform sponge structure.

(2) The sponge rubber board is mixed with nitrile reclaimed rubber vulcanization formula

60 parts of nitrile rubber, 40 parts of nitrile reclaimed rubber, 3.5 parts of zinc oxide, 2.5 parts of stearic acid, 1 part of antioxidant A, 1 part of antioxidant D, 10 parts of light calcium carbonate, 10 parts of magnesium carbonate, 40 parts of white oil ointment, 30 parts of dioctyl phthalate, 4 parts of foaming agent H, 0.7 parts of accelerator D, 1.3 parts of accelerator M, 1.4 parts of sulfur; Total 205.4 copies.

The use of nitrile reclaimed rubber can reduce the production cost of different types of rubber sheets, and reasonable design of the formula can give full play to the advantages of nitrile reclaimed rubber and improve the performance parameters and economic benefits of rubber sheets. In the actual production process, it is recommended to further optimize and adjust the formula of oil-resistant rubber sheet, conductive rubber sheet and sponge rubber board containing nitrile reclaimed rubber according to the specific application requirements and product performance requirements, improve the production process, improve the comprehensive performance of the finished product, and meet the physical property requirements of more high-performance rubber sheets.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits