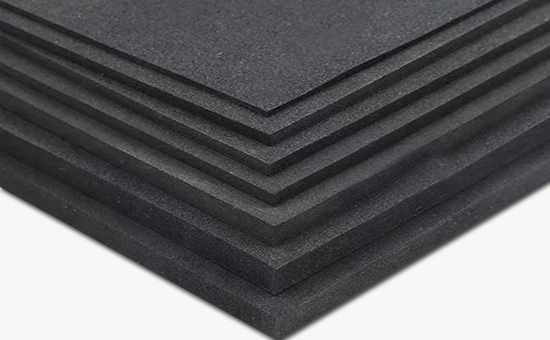

Sponge rubber sheet is an elastomer material containing a large number of evenly distributed tiny pores inside, which has the characteristics of good elasticity, light texture, sound absorption, shock absorption, heat insulation, etc., and can be divided into ordinary sponge rubber board, oil-resistant sponge rubber board, heat-resistant sponge rubber board, etc. Oil-resistant sponge rubber sheet is mainly used in E4LYY74 environments that need to be in contact with oil media, such as mechanical seals, automotive parts, etc. This type of sponge sheet requires excellent oil resistance, abrasion resistance and elasticity. In the production of oil-resistant sponge rubber sheets, the following kinds of reclaimed rubber are ideal choices.

1. Nitrile reclaimed rubber

Nitrile reclaimed rubber is a reclaimed rubber obtained by processing waste nitrile rubber products, which has excellent oil resistance and wear resistance. In actual production, nitrile reclaimed rubber can be used to replace part of the nitrile original rubber in the oil-resistant sponge rubber board, and the mixing ratio is generally 30%-50% to maintain the good mechanical strength and oil resistance of the oil-resistant sponge rubber board.

2. Sub-brand nitrile rubber

The sub-brand nitrile rubber has similar oil resistance, wear resistance, heat resistance and air tightness to the standard nitrile rubber, and has certain physical and mechanical properties such as tensile strength, hardness and elasticity, which can meet the basic performance requirements of the oil-resistant sponge rubber plate in actual use, and the price is much lower than the standard nitrile rubber, which can be used alone or combined with nitrile rubber to produce oil-resistant sponge rubber plate to reduce costs.

3. Neoprene reclaimed rubber

Neoprene reclaimed rubber has good oil resistance, heat resistance and elasticity, which is another option for the production of oil-resistant sponge rubber sheets. The mixing ratio of neoprene reclaimed rubber is generally 20%-30%, which can replace some neoprene or nitrile rubber. In the formulation design, neoprene reclaimed rubber can effectively improve the comprehensive performance of sponge rubber board and reduce the cost of raw materials.

4. Styrene-butadiene reclaimed rubber

Although the oil resistance of styrene-butadiene reclaimed rubber is not as good as that of nitrile reclaimed rubber, it can still provide better oil resistance to a certain extent. In the oil-resistant sponge rubber board, styrene-butadiene reclaimed rubber can be used in combination with nitrile reclaimed rubber and nitrile rubber, and the mixing ratio is generally 10%-20%, which has little impact on oil resistance and further reduces production costs.

Oil-resistant sponge rubber board uses nitrile reclaimed rubber, sub-brand nitrile butadiene rubber and other varieties of reclaimed rubber to reduce costs, generally using sulfur vulcanization, with accelerators D, M, DM, TMTD, etc.; The foaming system can use foaming agents H, OBSH, etc.; It is recommended to use light calcium and magnesium carbonate for the filling system; The softening plasticizing system can be used in combination with white oil paste and DOP; The use of general-purpose antioxidant A, antioxidant D, etc., to reduce costs while ensuring the oil resistance of the finished product.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits