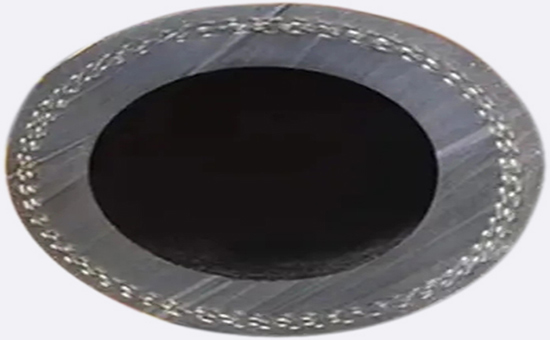

Rubber pipes are mainly used to transport various gases, liquids, viscous fluids and solid particle powders. They are widely used in the fields of industry and agriculture, energy, transportation and so on. According to the product structure, the rubber hose can be divided into several categories: cloth clamping hose, woven hose, wound hose, knitted hose and other hoses. The inner rubber of the coreless cloth clamping hose in the cloth clamping hose is mainly processed with natural rubber, CIS butadiene rubber and styrene butadiene rubber as the main raw materials. A large amount of recycled rubber can effectively reduce the raw material cost.

1. Natural rubber / cis-1,4-polybutadiene rubber / recycled rubber are used to produce the inner rubber formula of coreless cloth hose

30 parts of natural rubber, 70 parts of butadiene rubber, 140 parts of reclaimed rubber, 5 parts of zinc oxide, 3 parts of stearic acid, 1.6 parts of antioxidant, 50 parts of carbon black, 60 parts of light calcium, 63 parts of clay, 16 parts of rubber oil, 5 parts of coumarone, 2 parts of accelerator and 2.8 parts of sulfur; Total: 448.4 copies.

2. Use natural rubber / styrene butadiene rubber / reclaimed rubber to produce the inner rubber formula of coreless cloth hose

30 parts of natural rubber, 95 parts of styrene butadiene rubber, 75 parts of recycled rubber, 5 parts of zinc oxide, 2.5 parts of stearic acid, 2.5 parts of antioxidant, 60 parts of carbon black, 30 parts of clay, 110 parts of light calcium, 1.5 parts of accelerator and 2.5 parts of sulfur; Total: 414 copies.

3. Rubber matching skills for inner layer of coreless sandwich rubber hose produced by natural rubber / synthetic rubber / reclaimed rubber

In the production of coreless sandwich rubber hose with a large amount of recycled rubber mixed in natural rubber / cis-1,4-polybutadiene rubber and natural rubber / styrene butadiene rubber, it is recommended to use sulfur vulcanization, cooperate with accelerator CZ, and add a small amount of accelerator TMTD if necessary, which can better adjust the vulcanization degree and further improve the tensile strength, hardness and resilience of the inner layer of coreless sandwich rubber hose containing recycled rubber 2elyy513. In the reinforcement filling system, high wear-resistant furnace black can be used for reinforcement, such as N330; Match with an appropriate amount of n660 to improve the processability, resilience and flexibility of natural rubber / synthetic rubber / recycled rubber blends.

In actual production, in order to further improve the aging resistance of natural rubber / synthetic rubber / reclaimed rubber, an appropriate amount of antioxidant needs to be added to the formula. The commonly used antioxidant includes antioxidant a/d/aw, etc. the hose manufacturer can use two or more antioxidants together in an appropriate proportion to improve the aging resistance of the inner rubber of the coreless sandwich hose and effectively avoid problems such as frost spray and yellowing.

There are still many problems to pay attention to in designing the formula of coreless sandwich rubber hose with recycled rubber. I will continue to discuss relevant problems with you later.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits