Tire tread reclaimed rubber is made of tread rubber powder as raw material, processed by physical and chemical processes such as crushing, heating, mechanical treatment, etc., and the tread is the part with the highest rubber content and the best wear resistance in the tire, so the mechanical strength and wear resistance of the tread reclaimed rubber are higher than that of ordinary whole tire reclaimed rubber and sidewall reclaimed rubber; It can be used alone or combined with natural rubber and synthetic rubber to produce various hose inner layer glue, effectively reducing the cost of raw materials.

1. Tread reclaimed rubber production sandwich cloth feng shui hose inner rubber formula

10 parts of natural rubber, 45 parts of styrene-butadiene rubber, 45 parts of tread reclaimed rubber, 2.7 parts of zinc oxide, 1.3 parts of stearic acid, 1 part of antioxidant D, 28 parts of carbon black N660, 16 parts of light calcium carbonate, 48 parts of clay, 2.4 parts of coumarone resin, 0.8 parts of rosin, 4.3 parts of asphalt, 6.5 parts of tall oil, 0.9 parts of accelerator CZ, 0.2 parts of accelerator TMTD, 1.5 parts of sulfur; Total 213.6 copies.

10 parts of natural rubber, 35 parts of styrene-butadiene rubber, 55 parts of tread reclaimed rubber, 2.3 parts of zinc oxide, 1.2 parts of stearic acid, 0.7 parts of antioxidant A, 0.7 parts of antioxidant D, 0.6 parts of paraffin, 23 parts of carbon black N660, 27 parts of light calcium carbonate, 22 parts of clay, 0.9 parts of engine oil, 0.6 parts of accelerator DM, 0.8 parts of accelerator CZ, 1.5 parts of sulfur; Total 181.3 copies.

2. Tread reclaimed rubber produces coreless cloth hose inner rubber formula

10 parts of natural rubber, 40 parts of styrene-butadiene rubber, 50 parts of tread reclaimed rubber, 2.5 parts of zinc oxide, 1 part of stearic acid, 0.5 parts of antioxidant D, 0.75 parts of paraffin, 25 parts of carbon black N330, 40 parts of light calcium carbonate, 2.5 parts of gumaron resin, 2.5 parts of pine tar, 1 part of accelerator M, 0.05 parts of accelerator D, 0.1 part of accelerator TMTD, 2.1 parts of sulfur; A total of 178 copies.

35 parts of natural rubber, 65 parts of tread reclaimed rubber, 2.1 parts of zinc oxide, 1.4 parts of stearic acid, 0.35 parts of antioxidant A, 0.35 parts of antioxidant D, 0.3 parts of paraffin, 14 parts of carbon black, 14 parts of carbon black N774, 6.8 parts of light calcium carbonate, 1 part of pine tar, 0.4 parts of accelerator M, 0.1 part of accelerator DM, 1.4 parts of sulfur; Total 142.2 copies.

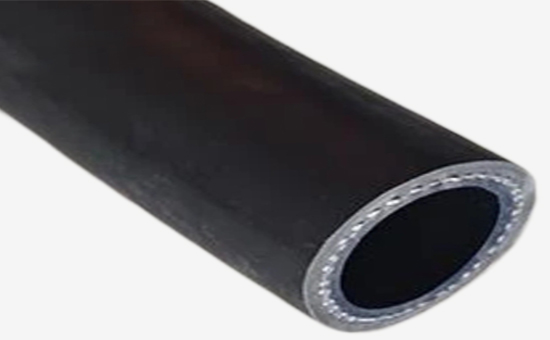

3. Tread reclaimed rubber produces suction pipes

100 parts of tread reclaimed rubber, 2.5 parts of zinc oxide, 2 parts of stearic acid, 1 part of antioxidant A, 1 part of antioxidant 4020, 18 parts of carbon black N660, 10 parts of light calcium carbonate, 5 parts of pine tar, 7.5 parts of coumaron resin, 0.55 parts of accelerator DM, 0.05 parts of accelerator TMTD, 1 part of sulfur, 0.8 parts of phthalic anhydride; Total 149.4 copies.

The rubber hose inner layer is an important part of the rubber tube, which is located on the inside of the pipe wall and is in direct contact with the gas, liquid or solid particles being conveyed. Its main function is to prevent media leakage, reduce abrasion E4LYY618 and chemical attack, while ensuring the overall performance and service life of the rubber tube. Tread reclaimed rubber can be used alone or in combination with natural rubber and styrene-butadiene rubber to produce various hose inner layer rubber, outer layer rubber, middle layer rubber, etc., and the follow-up editor will continue to discuss related issues with you.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits