Rubber products can be used in automobiles to transmit power and convey belt media, and play various functions such as shock absorption, buffering, sound insulation, and sealing. The automobile industry is the main market for rubber products. EPDM reclaimed rubber retains the basic performance characteristics of EPDM rubber, high and low temperature resistance, weather resistance, ozone resistance, and can replace high-priced EPDM raw rubber to produce automotive rubber products, effectively reducing raw material costs. The application of EPDM reclaimed rubber in the automotive industry mainly includes the following aspects.

1. Automobile hose

Vehicle hoses are mainly used to transport fuel, lubricating oil, water, gas and power, and are distributed in automobile chassis, engine and body parts. EPDM reclaimed rubber is widely used in automotive braking systems, cooling water systems, and air conditioning systems, including hydraulic brake hoses, radiator hoses, and high-pressure air conditioning hoses. In the production of automobile hoses, EPDM reclaimed rubber is often used in combination with EPDM rubber or other synthetic rubbers, which can effectively reduce the cost of raw materials on the premise of ensuring product quality.

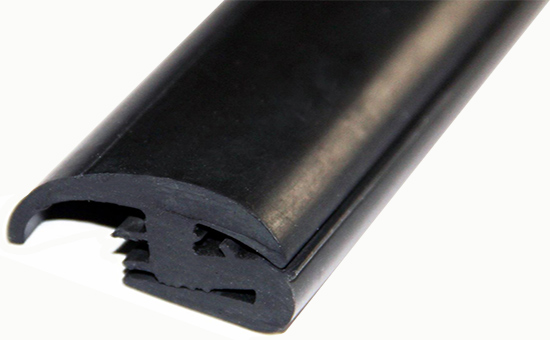

2. Rubber sealing products for vehicles

There are dozens of rubber sealing products in automobiles, including skeleton oil seals, O-rings, leather cups, films, dust jackets, door and window sealing strips, special-shaped sealing rings, etc. Dust and impurities enter the inside of the machine, shock absorption, sound insulation and heat insulation. EPDM reclaimed rubber can be used in combination with EPDM rubber to produce various sealing rings, door and window seals, dust jackets, etc., such as car window frame seals, door sponge sealants, windshield sealants, etc.

3. Car pull belt

Pull belts are mainly used among tires and other places. The function is to connect and tighten. During use, it needs to be exposed to sunlight, water, ozone, etc., and the short-term heat-resistant temperature needs to reach above 100 °C. When EPDM rubber and EPDM reclaimed rubber 2ELYY217 are used together to prepare pull tape, the proportion of rubber blending should be reasonably controlled, which can not only ensure the heat resistance and ozone resistance of the product, but also further improve the tensile strength and tearing of the finished product. Strength, elongation at break, hardness and other indicators.

4. The specific application of EPDM reclaimed rubber in automobile radiator hose

EPDM reclaimed rubber can be used together with EPDM rubber to produce automobile radiator hoses. The vulcanization system can be vulcanized with sulfur, with accelerators TMTD/BZ/DTDM, CZ/TMTD/TRA, etc.; Cross-linking additives are vulcanized, commonly used in combinations such as BIBP/TAC. The reinforcement system of automobile radiator hose is mostly reinforced with carbon black, such as carbon black N550, which has dispersibility in EPDM compound, good processing performance of vulcanizate, high temperature resistance and good thermal conductivity. The softening system can use paraffin oil to improve the temperature resistance of the rubber compound while softening.

EPDM reclaimed rubber is widely used in the automotive industry, especially in rubber pipes and automotive rubber sealing products; during the use process, the formulation of rubber products is rationally designed, and the production process is strictly controlled to reduce the production cost of automotive rubber products. Optimize finished product quality.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits