Nitrile rubber has excellent oil resistance and is an ideal raw material for the production of oil seals. In actual production, in order to ensure the sealing effect of the oil seal during use, certain requirements are put forward for the compression and permanent deformation of the rubber. How should the rubber product manufacturer improve? Will nitrile rubber products that need to work in solvents for a long time crack? Do nitrile rubber products have other special performance requirements, and how should manufacturers deal with these problems?

7. Solvent cracking

To improve the solvent cracking properties of nitrile rubber products, select nitrile rubber with medium and high acrylonitrile content; or use it with an appropriate amount of PVC to increase the crosslinking density and improve the solvent resistance of nitrile rubber. In actual production, improving the stress relaxation ability of nitrile rubber products can also improve the solvent resistance of the rubber compound, such as increasing the amount of non-reinforcing fillers. In addition, you can choose a suitable vulcanization system to increase the tear strength of the nitrile rubber. Theoretically, the high-sulfur vulcanization system is better than the low-sulfur vulcanization system. If necessary, reduce the amount of vulcanizing agent to improve the solvent cracking of the nitrile rubber.

8. Compression permanent deformation

To improve the compression set performance of nitrile rubber, use propylene oxide or low sulfur vulcanization, use carbon black with lower reinforcing performance, try to avoid using white carbon black and other white fillers, and use low-volatility antioxidants and plasticizers It can reduce the content of acrylonitrile under low temperature deformation.

9. Grindability

Reduce the elongation of nitrile rubber and reduce the wear resistance, and the nitrile rubber has better grinding properties. From the formulation point of view, the crosslinking density can be appropriately increased to reduce the elongation of the nitrile rubber compound. It is recommended to use ointment instead of part of the plasticizer, use white fillers such as light calcium 2YLYY929 and heavy calcium together, and use partially crosslinked nitrile For rubber, appropriately reduce the proportion of rubber used to improve the grindability of nitrile rubber. From the perspective of process operation, it is ensured that the filler and vulcanizing agent are uniformly dispersed in the rubber compound, and nitrile rubber products with better grinding properties can be prepared.

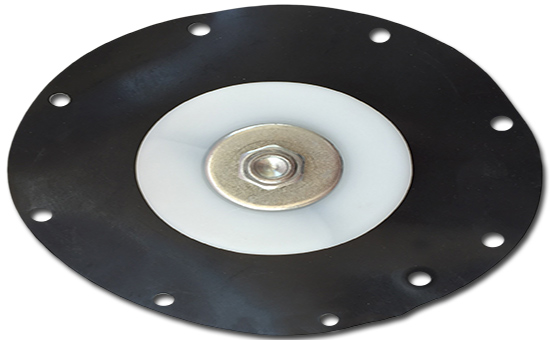

Nitrile rubber can be used to produce high oil-resistant rubber products such as oil seals, oil pipelines, chemical container linings, gaskets, etc., as well as ordinary oil-resistant products such as oil-resistant hoses, fuel tanks, printing rubber rollers, and oil-resistant gloves. It can also produce low-temperature oil-resistant rubber products, Oil-resistant and shock-absorbing products, etc. In actual production, nitrile rubber mixed with appropriate amount of reclaimed rubber can effectively reduce the cost of raw materials. Later editors will continue to share with you the production formula and production process points of nitrile rubber and nitrile rubber/reclaimed rubber products.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits