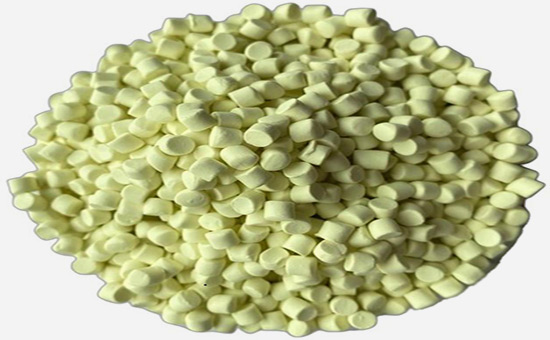

Nitrile recycled rubber has excellent oil resistance and good wear resistance, and can be used alone or in combination with nitrile rubber to produce oil-resistant and wear-resistant rubber products, effectively reducing raw material costs. When using nitrile recycled rubber to produce rubber products, taking appropriate measures to improve the processing performance and product quality of nitrile recycled rubber can further expand the application scope of recycled rubber? So how to do it?

1. Add nitrile original gum in an appropriate amount

When using nitrile recycled rubber as the main raw material to produce rubber products, adding 10%-30% nitrile original rubber can improve the physical and mechanical strength and oil resistance of the rubber material. or add 5-10 parts of liquid nitrile rubber to replace part of the solid nitrile original rubber, combined with plasticizer, to reduce the viscosity of the compound Mooney and improve the fluidity.

2. Rationally design the formula of nitrile recycled rubber products

Nitrile recycled rubber products When producing rubber products, reasonable design of formulas can further improve the performance of rubber processing technology and the comprehensive indicators of finished products, and reduce more raw material costs, mainly including vulcanization system, reinforcement filling system, and softening plasticization system.

(1) Vulcanization system

The most commonly used sulfur accelerator system for nitrile recycled rubber products is the sulfur accelerator system, and it is recommended to use ordinary sulfur vulcanization system for rubber products with high requirements for the physical and mechanical properties of the rubber material. NBR recycled adhesives with low sulfur and high sulfur pro-vulcanization systems have good heat resistance, low compression deformation, and are not easy to burn. Sulfur-free sulfur-containing compound systems can be improved by autumn rum (such as TT/DM), which can be improved with dithiodimorpholine or CZ to improve the problem of frost spraying. Nitrile recycled adhesive vulcanized with peroxide (DCP) vulcanization is heat-resistant and cold-resistant, has low compression deformation, but has high cost and slow vulcanization, and can be added with HVA-2 and other co-crosslinking agents.

Rational design of the vulcanization system of nitrile recycled rubber products needs to take into account the oil resistance, low compression set and heat resistance of the rubber material, and improve the quality of nitrile recycled rubber products.

(2) Reinforce the filling system

To improve the mechanical strength of nitrile recycled rubber products, high wear-resistant carbon black or general furnace black can be used to reinforce it, which can significantly improve the strength and wear resistance of nitrile recycled rubber vulcanized rubber. hard clay, activated magnesium oxide, and activated calcium carbonate E5LYY725 have a certain degree of reinforcing effect; The elasticity of the terracotta clay is poor, the permanent deformation is large, and the vulcanization will be delayed, so use it as little as possible. Calcium carbonate can be filled in large quantities for volume increase and cost reduction; When used in combination with active reinforcing fillers (reinforcements), it can improve processing performance and improve physical and mechanical properties.

The use of nitrile recycled rubber to produce ordinary oil-resistant products requires good oil resistance, aging resistance, low compression deformation and necessary physical and mechanical properties. When high elongation and wear resistance are required, carbon black with high reinforcement must be selected, such as ISAF, HAF, etc.; Coarse-grained soft carbon black is conducive to improving the rebound rate of the compound. Nitrile recycled rubber products can also be reinforced with silica (light-colored products), thermosetting phenolic resin, and polyvinyl chloride resin, and vulcanized rubber has good strength, heat resistance and oil resistance.

(3) Softening and plasticizing system

The commonly used plasticizers of nitrile recycled rubber products are dibutyl phthalate (DBP), dioctyl phthalate (DOP), xylene phosphate (TCP), etc., liquid nitrile rubber and polyester can be used as plasticizers to prevent extraction, dioctyl sebacrate and dioctyl adipate have superior cold resistance, and coumarone resin also has a great effect on improving the adhesion of nitrile recycled adhesive. When preparing extruded products of nitrile recycled rubber, use 5-20 parts of paste, which can make the adhesive shrink smaller and the surface smooth, and special attention needs to be paid to the changes in physical and mechanical properties and heat resistance and aging resistance.

3. Improve the processing technology of nitrile recycled rubber products

(1) Compounding process: using low temperature (≤60°C), small roller spacing (2-4mm), and segmented mixing, which can avoid scorching caused by excessive heat generation; When using nitrile recycled glue and nitrile original glue together, it is recommended to add recycled glue and softener, and then gradually add small materials such as carbon black and sulfur.

(2) Vulcanization process: the vulcanization temperature is 150-170 °C, and the time is adjusted according to the thickness of the nitrile recycled rubber product (usually 10-30 minutes) to ensure that the rubber material is fully cross-linked.

To improve the processing performance and product quality of nitrile recycled rubber, rubber product manufacturers can also pre-treat rubber materials and compounds, and regularly sample and test finished products, which can significantly improve the processing performance and product quality of nitrile recycled rubber and meet the performance needs of more oil-resistant and wear-resistant rubber products.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits