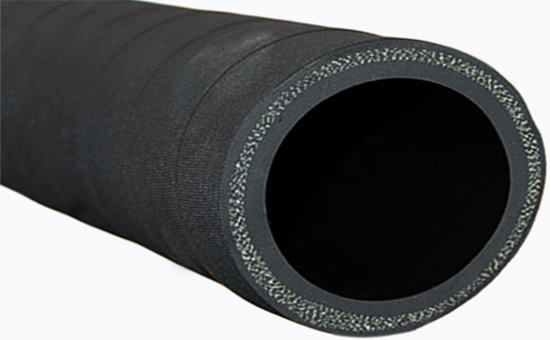

Ordinary hose is a cloth hose that conveys air, other inert gases, water or other neutral liquids at room temperature, and the rubber materials of each component include inner glue, wiping rubber, filler glue, and outer glue, etc., which are generally processed with natural rubber, styrene-butadiene rubber, and butadiene rubber as the main raw materials. In actual production, the performance requirements of rubber compounds for different parts of ordinary hoses are different, which parts can be mixed with reclaimed rubber to reduce costs?

1. The inner layer of ordinary hose is mixed with reclaimed rubber

The inner layer of the ordinary hose is the first working surface of the conveying medium, which requires the rubber to have good compactness, adaptability to the conveying medium, and certain elasticity, softness and aging resistance, and the raw materials used are mainly natural rubber and styrene-butadiene rubber, or the NR/SBR/BR is used together; The appropriate amount of reclaimed rubber is mixed, and the glue content of the formula is controlled among 25%-30%, which can not only reduce the cost of raw materials, but also improve the performance of rubber processing technology.

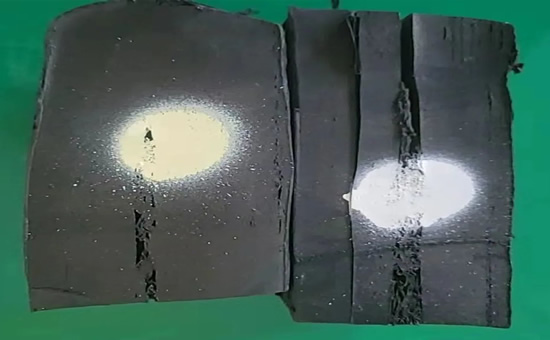

2. Ordinary hose wiping cloth glue mixed with reclaimed rubber

The main function of this part is to firmly combine the skeleton layer and among the skeleton layer and the inner and outer rubber layers, and the rubber material E4LYY41 has good fluidity, permeability to the fabric, as well as certain tensile properties and flexural fatigue resistance. The formula of ordinary rubber hose wiping rubber is mainly based on natural rubber, with an appropriate amount of styrene-butadiene rubber, butadiene rubber, neoprene rubber and reclaimed rubber, etc., and the general glue content is controlled among 35%-40%.

3. Ordinary hose filler is mixed with reclaimed rubber

Ordinary hose filler is intermediate glue and middle glue, which mainly plays the role of filling and bonding the skeleton and glue layer, and requires the rubber material to have good adhesive performance, elasticity, flexibility and flexural resistance. The rubber hose intermediate rubber formula is usually based on natural rubber, with an appropriate amount of styrene-butadiene rubber, butadiene rubber or reclaimed rubber, and the glue content of the normal formula is controlled at about 35%.

4. The outer rubber of ordinary hose is mixed with reclaimed rubber

The outer layer of rubber is the second working surface of the ordinary hose, which is exposed to air for a long time, which plays a role in protecting the inner structure of the hose from external wear, aging and corrosion, and requires the rubber to have good wear resistance, tear resistance or weather aging resistance. The outer rubber formula of ordinary hoses is generally based on neoprene, which is used in combination with an appropriate amount of natural rubber and styrene-butadiene rubber, and an appropriate amount of reclaimed rubber is mixed with it, and the glue content is generally controlled among 30% and 35%.

Theoretically, the inner layer of the hose, the wiping rubber, the filler glue and the outer layer of the rubber can be mixed with a certain proportion of reclaimed rubber, mainly tire reclaimed rubber, and the reasonable design formula can further optimize the quality of the hose while reducing costs. In the future, Xiaobian will continue to share with you the key points of formula design and vulcanization formula of different adhesive layer parts of ordinary rubber hoses produced by reclaimed rubber.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits