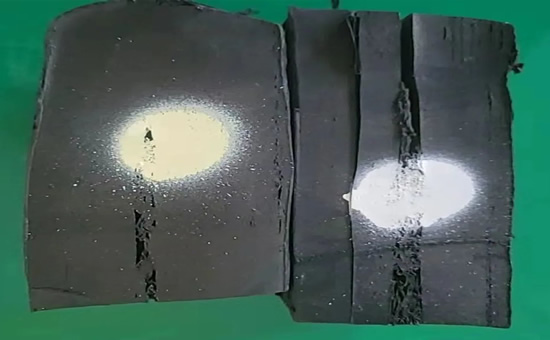

Some rubber products need two glues to be used together or printed on the surface of the rubber product, but yellowing may occur during use, which not only affects the aesthetics of the product, but also reduces the quality of the product service life. For the white hemming of the black sole and the white words printed on the rubber tube, how to avoid yellowing? This article will start with non-migrating plasticizers and the selection of non-migrating tire reclaimed rubber, and introduce them in detail.

1. Non-migrating plasticizer for rubber

Plasticizers commonly used in rubber products include phthalates, phosphates, epoxy resins, etc. Although these plasticizers can improve the softness and ductility of rubber products, they also gradually migrate over time, causing rubber products to turn yellow. In order to avoid plasticizer migration in rubber products, we can take the following measures:

1. Choose a low-migration plasticizer

Low-migration plasticizers refer to plasticizers that will not easily migrate out after being used in rubber products. The use of this plasticizer can effectively avoid the yellowing problem of rubber products. At present, there are already some low-migration plasticizers on the market, such as environmentally friendly plasticizers, which can be selected by us.

2. Control the amount of plasticizer

Excessive use of plasticizers can also cause yellowing of rubber products. Therefore, in the process of producing rubber products, the amount of plasticizer used should be controlled to avoid excessive use.

3. Add antioxidant

Antioxidants can effectively delay the aging rate of rubber products, thereby reducing the migration of plasticizers. An appropriate amount of antioxidants can be added to the vulcanization formula, which also prolongs the service life of rubber products.

Second, choose HONGYUN non-migrating tire reclaimed rubber

Tire reclaimed rubber refers to the rubber material recovered from waste tires, which is processed and used again to produce rubber products such as tires. Due to the different types and quantities of additives contained in different waste tires, some tire reclaimed rubber used as primer does not turn yellow, and some turn yellow. In order to avoid this situation, it is recommended to choose non-migrating tire reclaimed rubber.

d06m06yyE3 Non-migrating tire reclaimed rubber means that the surface color of black tire reclaimed rubber will not change color over time, and will not migrate and pollute laminating glue or printed characters. The first screening has been carried out when selecting waste tires. If the rubber powder cannot be collected outside, it will not migrate. Environmentally friendly plasticizers and other additives are used in the desulfurization process, thereby avoiding the migration of tire reclaimed rubber color or plasticizers.

In order to avoid the yellowing of the white edge of the black sole and the white words printed on the rubber tube, we can start from two aspects: migration of plasticizer for rubber and selection of non-migrating tire reclaimed rubber. In the production process, we should choose low-migration plasticizers, control the amount of plasticizers used, and add antioxidants to avoid the migration of plasticizers. At the same time, non-migrating tire reclaimed rubber can also be used to avoid the migration of plasticizers in the reclaimed rubber. These measures can not only improve the quality of rubber products, but also reduce the cost of raw materials, save electricity costs, and improve the recycling rate of resources.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits