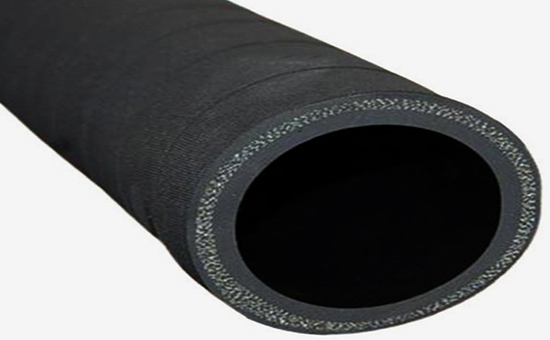

Rubber tubes are flexible tubular rubber products used to transport various gases, liquids, viscous fluids and solid particles under positive or negative pressure, and are widely used in industry, agriculture, energy, transportation and other fields, and are processed from natural rubber and synthetic rubber as raw materials. As a renewable resource for waste rubber recycling, the price is much lower than that of virgin rubber, can it be used in the production of rubber tubes? What hoses can use recycled rubber to reduce costs?

1. Ordinary hose

Ordinary hoses are mainly used to transport air or other inert gases and transport water or other neutral liquids at room temperature, and the rubber materials of each component include inner rubber, wipe rubber, filler rubber and outer rubber, etc., mostly made of natural rubber, styrene-butadiene rubber, butadiene rubber, neoprene and other raw materials, and the appropriate amount of tire recycled rubber can effectively reduce the cost of raw materials.

When mixing recycled glue into each layer of ordinary hose, it is necessary to reasonably control the glue content of the formula. The inner layer of ordinary hose is generally composed of natural rubber and styrene-butadiene rubber, which can be mixed with tire recycled rubber in an appropriate amount, and the glue content is controlled at 25%-30%; The formula of ordinary hose rubber is mainly natural rubber, which can be combined with an appropriate amount of general synthetic rubber and tire recycled rubber E5LYY410, with a glue content of 35%-40%; Ordinary hose filler rubber is usually based on natural rubber, and can be used in combination with an appropriate amount of styrene-butadiene rubber, butadiene rubber, etc., and an appropriate amount of tire recycled rubber can be used; The outer rubber formula of ordinary hoses is usually based on neoprene, and is used in conjunction with natural rubber, styrene-butadiene rubber and other general rubbers, and tire recycled rubber is used with a glue content of about 35%.

2. Acid and alkali resistant hose

Acid and alkali resistant hoses are mainly used to transport acid, alkali and other corrosive media, and for acid and alkali resistant hoses that are generally not strong in corrosiveness, natural rubber can be used or used in combination with styrene-butadiene rubber and neoprene, and tire recycled rubber can be mixed with an appropriate amount to reduce costs.

3. Oil-resistant hose

Oil-resistant hose refers to a hose that can resist the erosion of oil media, mostly based on nitrile rubber, or it can be used in combination with an appropriate amount of neoprene, or it can also be blended with other polymers such as polyvinyl chloride to obtain better oil resistance and comprehensive performance. In actual production, an appropriate amount of tire recycled rubber can be mixed in the outer layer of oil-resistant rubber and rubber, and a small amount of tire recycled rubber can also be mixed with a small amount of tire recycled rubber in the inner layer of some oil-resistant rubber pipes to ensure the oil resistance of the rubber and reduce the cost of raw rubber.

4. Rubber tube vulcanization formula mixed with tire recycled rubber

(1) The inner layer of the ordinary hose is mixed with the vulcanization formula of tire recycled rubber

50 parts of natural rubber, 50 parts of tire recycled rubber, 2.5 parts of zinc oxide, 1.8 parts of stearic acid, 1 part of anti-aging agent A, 1 part of anti-aging agent D, 30 parts of spray carbon black, 53 parts of light calcium carbonate, 9 parts of heavy oil, 0.8 parts of paraffin, 0.45 parts of accelerator M, 1.45 parts of sulfur; A total of 201 copies.

(2) The vulcanization formula of tire recycled rubber mixed with the outer layer of ordinary hose is mixed

35 parts of natural rubber, 30 parts of styrene-butadiene rubber, 35 parts of tire recycled rubber, 2.7 parts of zinc oxide, 1.3 parts of stearic acid, 0.7 parts of anti-aging agent A, 1 part of anti-aging agent D, 1.3 parts of paraffin, 27 parts of carbon black N330, 73 parts of light calcium carbonate, 0.5 parts of pine tar, 7 parts of No. 30 engine oil, 1.6 parts of accelerator M, 0.7 parts of accelerator DM, 1.8 parts of sulfur; Total 218.6 copies.

(3) The outer layer of the oil-resistant hose is mixed with the vulcanization formula of tire recycled rubber

Nitrile 15 parts, neoprene 60 parts, tire recycled rubber 25 parts, zinc oxide 3.8 parts, stearic acid 2.5 parts, magnesium oxide 4.2 parts, anti-aging agent D 1.6 parts, carbon black N330 25 parts, carbon black N774 25 parts, terracotta 23 parts, motor oil 10 parts, dibutyl phthalate 4.2 parts, coumalong resin 11 parts, accelerator D 0.4 parts, accelerator TMTD 0.25 parts, sulfur 0.45 parts; Total 211.4 copies.

Tire recycled rubber is made of waste tire rubber parts as raw materials, after crushing, desulfurization, refining and other processes, with the basic performance characteristics of rubber, good compatibility with natural rubber and general synthetic rubber, and can be used with natural rubber and synthetic rubber to produce rubber tubes to reduce raw material costs. The amount of tire recycled rubber in different varieties of hoses is different, and the proportion of tire recycled rubber in different parts of the same hose is also different, and we will continue to discuss related issues with you in the future.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits