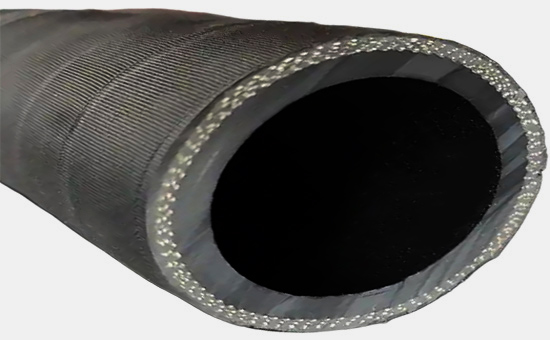

Heat-resistant rubber pipe is a tubular heat-resistant rubber product processed from rubber as the main material and used to transport high-temperature gases, liquids and slurries, which can maintain stable performance at higher temperatures, and is generally composed of inner rubber, outer rubber, intermediate rubber and skeleton layer. EPDM rubber has excellent heat resistance, weather resistance and ozone resistance, and is an ideal raw material for the production of heat-resistant hoses. EPDM reclaimed rubber is used to replace a certain proportion of EPDM original rubber to produce heat-resistant hoses, which effectively reduces the cost of raw materials.

1. The advantages of heat-resistant hoses mixed with EPDM reclaimed rubber

EPDM reclaimed rubber is a recycled rubber processed by classification, crushing, desulfurization, filtration and other processes of EPDM head glue, unvulcanized EPDM rubber or waste EPDM rubber products, which retains the basic performance characteristics of EPDM original rubber, excellent high and low temperature resistance, excellent aging resistance, much lower price than original rubber, better fluidity and plasticity, and replaces part of EPDM original rubber to produce heat-resistant rubber hoses that can effectively reduce the cost of raw materials and improve the performance of rubber processing technology under the premise of ensuring the performance of the hose.

2. Selection skills and mixing ratio of EPDM reclaimed rubber for heat-resistant hoses

When EPDM heat-resistant hoses are mixed with EPDM reclaimed rubber to reduce production costs, it is recommended to use EPDM reclaimed rubber with high ethylene propylene content for heat-resistant hoses with higher temperature requirements, which has better heat resistance; For heat-resistant hoses with thin wall thickness, it is recommended to use high-fineness EPDM reclaimed rubber (60-80 mesh) to ensure smooth extrusion of the hose; When the heat-resistant hose has requirements for environmental performance, choose the environmentally friendly EPDM reclaimed rubber that can provide relevant test reports to meet the environmental protection requirements.

The mixing ratio of EPDM reclaimed rubber in heat-resistant hoses needs to be determined according to the physical property requirements of the hose and the performance indicators of EPDM reclaimed rubber, which is generally controlled among 20% and 50%.

3. Key points of formula design of heat-resistant hose mixed with EPDM reclaimed rubber

When mixing EPDM reclaimed rubber in heat-resistant hoses with EPDM rubber as the main raw material, low-sulfur and high-promotion vulcanization systems or peroxide vulcanization systems are mostly used, and the heat resistance of vulcanized rubber is better. When carbon black reinforcement is used, semi-reinforced carbon black E5LYY225 and general furnace black can be used together, and the vulcanized rubber can obtain high elasticity, low heat generation, good aging resistance and flexural resistance; Light-colored inorganic fillers with less water absorption have better heat resistance than carbon black; When using softeners to improve the processing performance of EPDM rubber/EPDM reclaimed rubber, use less or no low-boiling point softeners as much as possible.

When using EPDM reclaimed rubber to produce high-performance and low-cost heat-resistant hoses, rubber product manufacturers not only need to select the appropriate EPDM reclaimed rubber, reasonably determine the proportion of reclaimed rubber and adjust the formula appropriately, but also need to adjust the production process parameters, especially the mixing process and vulcanization process, and discuss related issues with you later.

Hongyun environmental protection EPDM reclaimed rubber is made of EPDM head glue as the main raw material, with high and low temperature resistance, anti-aging, high insulation, ozone resistance, erosion resistance and other physical properties, compared with the sealing strip EPDM regeneration also has the characteristics of high glue content, high fineness, tastelessness, good elasticity, etc., is an ideal raw material for the production of extruded EPDM products to reduce costs, and a certain proportion of environmentally friendly EPDM reclaimed rubber can be mixed with a certain proportion of environmentally friendly EPDM reclaimed rubber in the heat-resistant hose can greatly reduce the cost of raw materials while ensuring the quality of rubber products.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits